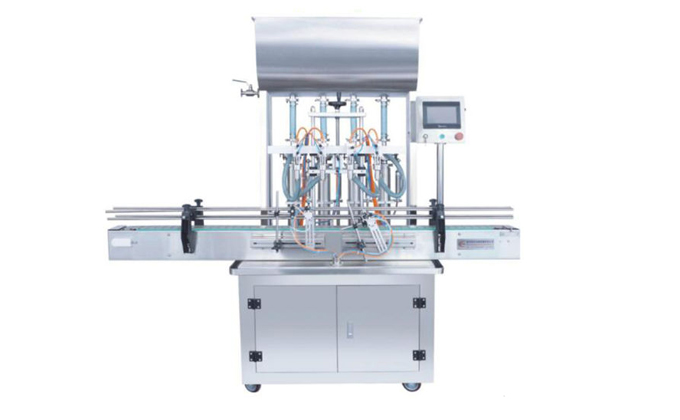

Introduction of Bottle Filling and Capping Machine

The automatic rotary filling and capping machines are suitable for filling thin to medium thickness packaging for products, such as liquid medicine, toner, air freshener, skin care, tea drinks, fruit juice etc. They are widely used in the pharmaceutical, pesticide, daily chemical, food, and other industries.

Working Principle of Bottle Filling and Capping Machine

Production Flow:

Filling–Feeding Inserts–Pressing Inserts–Feeding Caps–Capping

- Bottle entering way: operators put the empty bottles on the turntable, with the table rotating and the weight of bottles themselves, they will be sent to the conveying belt.

- Bottle detecting device: the photoelectric sensor will detect if there are any positions on the turntable that lack a bottle and send the detection signal to computer to control material filling (has bottle) or not (no bottle).

- Filling device: if filling and capping machine detects a bottle in the front station, PLC control the filling mouth entering the bottle to fill material; if no bottle is detected, there will be no filling.

- Capping device: arrange the caps automatically through vibration plate or elevator. With vacuum technology taking caps to cap on the bottle, it’s more efficient and stable.

- Servo screwing: if there is cap detected, the servo motor will control the twisting force and rotating speed to ensure that the cap is screwed up with same tightness.

- Bottle discharge: the well-screwed bottles will be discharged and transmitted to the next procedure.

Features of Bottle Filling and Capping Machine

- The filling temperature of this machine is 55-95ºC hot filling, it is the preferred equipment for hot-filling drinks

- Automatic cream filling machine adopts suspension air conveyor. When changing the bottle

- It only needs to adjust the conveying width, which is more efficient and labor-saving

- Filling action is smooth, fast, precise, reliably sealed, creates low material loss and has many other functions. It also avoids secondary pollution or contamination of materials effectively

- It adopts advanced technologies such as human-machine interface touch control system, PLC computer control, frequency converter control, etc. It has high degree of automation and is easily operated

Applications of Bottle Filling and Capping Machine

This bottle filling machine can be used in the pharmaceutical, pesticide, daily chemical, food, and other industries. For manufacturers in those industries, choosing plastic bottles or glass bottles as packaging containers, this machine can fill the facial cream, grease, paste, gel or viscous fluids into bottle for capping and screwing, and finally output the finished product.