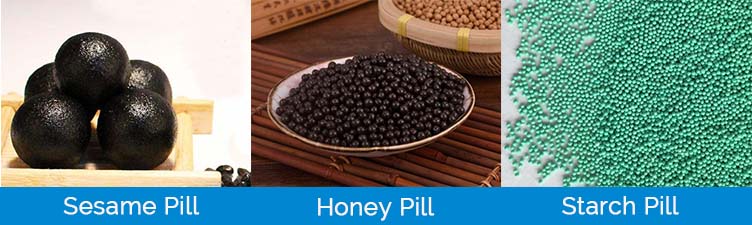

Automatic traditional chinese medicine pill making machine is the large-scale traditional herbal pill making machine which is the highest production efficiency machine in domestic and overseas at present. It can produce pill diameter from 3 to 12mm such as small honey pill, water honey pill, condensed pill and starched pill. With special design and fabrication processing, it can also produce the ceramic pill, molecular sieve pill in chemical industry and various food pill, flour pill, etc. This machine is the ideal preferred equipment for different pharmaceutical manufacturers, hospital preparation room and food manufacturers.

Structure of Herbal Pill Making Machine

- This pill making machine is composed of two parts: strip discharging and pill making, box structure, horizontal discharging, simple structure, easy to operate and convenient to maintain.

- The worm gear reducer is used for delivery, and the transmission is stable and reliable.

- The pill rolling and pill cutting mechanism of the pill making part is in a gearbox, the machine parts are in good lubrication conditions, and the pill cutting speed can be adjusted by stepless speed changer.

- The feeding port is large, and the pressing plate is turned to press the material, which is convenient for filling and can prevent the phenomenon of shed material. The hopper is bounded by the flap shaft, which is divided up and down, which is very convenient to disassemble during cleaning.

- Electric heating adopts electric heating tube, which is safe, reliable and smooth.

- Use alcohol to instill the medicine strips. The pill-making knife is equipped with a brush on the outside to prevent the sticking of the knife. The alcohol is installed in the square box of the stripping mechanism. The amount of alcohol is adjusted through a ball valve.

Basic Operation

- Prepare materials, add powders and excipients according to the ratio of ingredients

- Mixing, mixing the blended materials

- Press, roll the mixed materials into a cylindrical shape or a round shape and press the cake at the cake pressing station

- To make slabs, put the cakes pressed at the cake pressing station to the slab making station for making

- Pill making, place the strips made at the pharmaceutical pill making machine station horizontally on the pill making station

- Dry, put the prepared pills in a drying pot for 3-5 minutes to get out

- Finished product

Instructions for Use

Working Environment

This machine is suitable for indoor environments where the ambient temperature is -5°C to +40°C, the relative humidity is less than 90%, the grid voltage amplitude fluctuation is less than 10% of the rated value, and there is no conductive dust or corrosive metal gas around. It is installed in a sunny and clean factory. For safety reason, a grounding wire must be used.

Pre-start inspection

Before starting, the oil cup on the hopper must be filled with edible oil; check whether the pill making machine is aligned and tightened; whether the cleaning system is unblocked and adjust the appropriate amount. Use alcohol to disinfect the guide wheel, guide frame, pill knife, etc. Turn on the electric heating.

Raw Material Filling

The strip part runs idling for 3-5 minutes, and the material can be fed without exception, and the strip can be pushed out. Return to the part of the hopper, and then start the pelletizing part after the material strip is qualified. The feeding should be even during operation. If it is found that the delivery and pelletizing are not synchronized, it can be adjusted by the knob. Clockwise pelletizing is fast, and counterclockwise pelleting is slow. The size of the pellet diameter can be achieved by changing different outlets, pelletizing knives and guide wheels.

Ensure Work Safety

Do not put foreign objects into the hopper when feeding, and do not put your hands into the upper plane of the hopper, so as not to hurt your hands by the pressure plate. Always check the various parts for any abnormalities, and stop for inspection immediately if any abnormalities are found.

Cleaning the Machine

After use, turn off the main switch and other switches after power off. When cleaning, first remove the strip opening, electric heating cover, and unload the machine head, you can use the hook-shaped handle (special), and then pull out the bracket and the pusher. Disassemble the upper part of the hopper to clean the two flap shafts, and apply edible oil after cleaning. Degreasing and disinfecting all parts with alcohol when reusing.

Precautions for Oil Changes

The oil in the reducer should be kept on the no oil mark, and the waste oil should be drained and replaced with new oil after two to five man-months of normal work. Add cooking oil to the oil cup on the hopper three times per shift, and add proper amount of oil to the other gear sprocket points.

Reference Formula of Chinese Medicine Pills

- The medicine is sun-dried and processed into powder, the fineness of which is over 80-100 mesh baskets, rehmannia and other medicines, using a meat grinder method to repeatedly twist multiple times to reach mud.

- Medicinal powder, rice soup (the rice is made into porridge, and the sticky liquid is removed from the rice grains is the rice soup), honey, a small amount of dextrin (the ratio of medicinal noodles to honey is 10:1, and the rice soup is appropriate), stir into a dough shape. Special attention: the viscosity of the powder should be moderate, not too soft or too hard to stir evenly and not sticky.

- Dextrin must be boiled with water to form a paste, and a spoon must be used for constant stirring when boiling.

- It is strictly forbidden to add edible oil on the pill output shaft during use, otherwise the pill sticking knife will not fall off easily.

- Pay attention to when mixing the powder: Chinese medicine is a non-sticky material, and a certain proportion of medicinal excipients needs to be added. When making pills, the viscosity of the surface of the medicine should be moderate to prevent it from being too soft or too hard, and it should be stirred so that it does not stick to your hands.

SED has pill making machine for sale, together with other tablet machine such as granulator machine for pharmaceuticals, powder mixing machine, tablet pressing machine and so on!

Please feel easy to contact us if you are interested or have something concerned.