Rotary tablet press is a type of tablet press that was designed to deal with the defects of single punch tablet press, such as uneven density inside the tablet. The tablet press presses up and down uniformly at the same time, so that the air in the drug particles has ample time to escape the die hole, greatly improves the uniformity of the tablet density, and reduces the phenomenon of splintering. And this type of tablet press also has the characteristics of small machine vibration, low noise, low energy consumption, high efficiency and accurate tablet weight. In addition to rotary tablet presses, there are also single punch tablet press, and high-speed rotary tablet press can be selected.

After the tablet pressing, a elevating tablet deduster will be a good choice for powder removal.

The Prospect of Tablet Press

According to “Tablet Processing and Packaging Equipment Market – Global Opportunity Analysis And Industry Forecast (2017 – 2022)” The global tablet processing & packaging equipment market will increase at a CAGR of 8.8% from 2017 to USD 5,268.8 million by 2022, driven by growing aging population, increasing chronic and infectious diseases, increasing growth of pharmaceutical market, and various technical advancements.

In the era of high competition and increasing antibiotic resistance, the R&D and F&D departments of pharmaceuticals sector are pressurized to develop more and more drugs to fight against the powerful bacteria and chronic diseases. In addition, the rising demand for pharmaceutical products due to aging population & growing prevalence of chronic diseases across the globe are pressurizing the manufacturing companies to increase their production.

This results in increased demand for pharmaceutical processing equipment as it helps in manufacturing of tablet at different stages to overcome the problems associated with traditional approaches which used labour-intensive methods that resulted into the increased manufacturing time and production cost. Hence, the adoption of various automated equipment’s available for different stages of tablet manufacturing is increasing to reduce the errors and manual work to great extent and increase the efficiency of tablet processing & manufacturing.

The Working Process of the Tablet Press

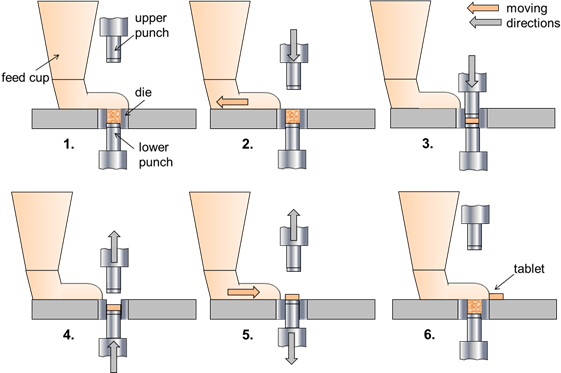

The working process of the tablet press can be divided into the following steps:

- The punch position of the down punch (its working position is upward) extends from the lower end of the middle mold hole into the middle mold hole to seal the bottom of the middle mold hole

- Use a feeder to fill the middle mold hole with medicine

- The punch part of the upper punch (its working position facing downwards) falls from the upper end of the middle die hole into the middle die hole, and goes down a certain stroke to compress the powder into tablets

- The upper punch lifts out the hole. The downward punching and rising will push the tablets out of the middle die hole to complete a tablet pressing process

- The undershoot drops to the original position, ready for the next filling

Applications of Rotary Tablet Press

- Different Shapes Can Be Compressed

This kind of automatic rotary tablet press has the function of pressing the grain material or powders to be round or irregular shape tablets, such as candy, calcium tablets double-sides with letter printing and etc.

- Raw Material

The rotary tablet press is a machine with automatic rotation, frequency control, and continuous tablet compression. It is mainly used in the manufacture of tablets in the pharmaceutical industry. It is also suitable for pressing granular raw materials into tablets in the chemical, food, and electronic industries. This machine is generally not suitable for the pressing of semi-solid, overlapping particles, low melting point, moisture-prone raw materials and powder without particles.

- Industry

A tablet press machine is widely used to press tablets of different shapes and sizes for industries such as;

>Pharmaceutical

>Nutraceutical

>Cosmetics

>Ayurvedic

>Herbs

>Fitness

>Confectionary

>Cleaning products industry

>Industrial pellets manufacturing

>Mining

- Colour

Whether it’s a single color, two-color or multi-color, the tablet press can perfectly meet your requirements

What Are the Advantages of Rotary Tablet Press?

- Multi-station tablet press which is also known as a rotary tablet press packs a myriad of advantages.

- Guarantees a higher output as high production levels can be achieved with a minimal amount of labor

- Transparent windows so that press condition can be observed clearly and the windows can be opened. Cleaning and maintenance is easier

- Higher outputs of between 100,000-170,000 tablets per hour save time and enable you to meet your large production demands

- Presses up and down uniformly at the same time, avoiding uneven density

- Powder filling can be made easy by using an automatic feeding mechanism

- It reduces wastage of material

- It allows independent control of both the weight and hardness of tablets